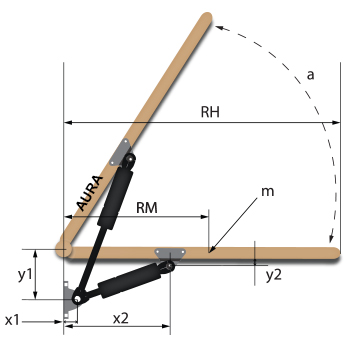

C = stroke of linear actuator:

C = 1/3 of RH (For opening at 90° )

Attention the calculation of the race (and of x2) is valid for 90% of the cases.

|

mm |

F1 = force / pressure of the electric cylinder:

Tolerance = +/- 40 Newtons

|

Newtons |

N = Number of actuators needed:

Stroke and force are calculated for each actuator(s)

|

vérin(s) |

y1 :

Caution - The dimension y1 must be 100 mm less than the stroke of the actuator

|

mm |

x1 :

The more the cylinder attachment is moved away from the axis of rotation of the hatch, the better the action of the linear actuator.

= ideal open the hatch at 80°

|

50 to 80 mm on average |

|

This calculation tool is only valid for the type of layout above (see photo)

The calculation is reliable at around 90% - Our customers use this tool every day without encountering any problems

However, it is compulsory to check the result obtained with the help of a drawing (cylinder folded and cylinder extended).

This result proposal does not engage the responsibility of Motionproplus.com under any circumstances.

These calculations must be validated by a design office.

This tool is valid for an object with a centered center of gravity: uniform mass.

We remind you that the electric actuator is not a safety element.

To block a position, you must additionally use a mechanical blocking

|